Peripheral equipment

Magnetic cylinder

- - A strong 2200 Gauss magnet positively secures the Pinnacle Die.

- - Scratch-resistant journal by quench hardening

- - Bearer replaceable structure cylinder

- - Pre-processed gears (50 to 154) are available for label printers.

- - Max. cylinder size: 1,050mm(L) x 250mm (Dia.); surface length: 900mm; Max. load: 200kgs

- - Feel free to contact us for your special requirement specs.

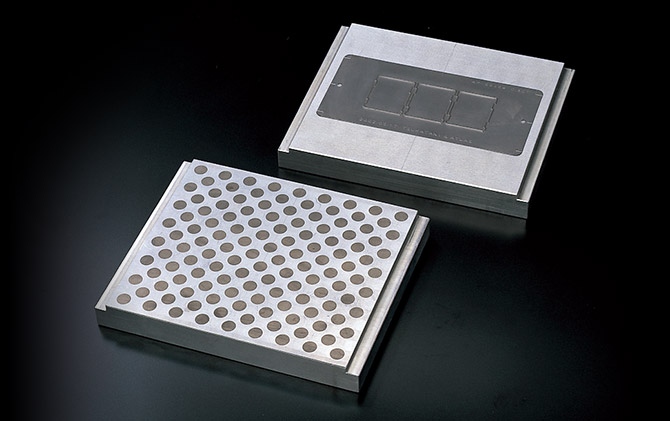

Magnetic plate & aluminum plate

- - Magnetic plate and aluminum plate are made from hard aluminum, which render themselves resistant to impact. For flat die cutting, the magnetic plate is recommended to ensure easy setting.

- - Parallel ground magnetic late assured the cutting ability of the Pinnacle Die whose edge height is finished to an accuracy of ±0.003mm (±0.005mm).

- - Thickness of 7mm to 24mm are supported. [Max. size: 250mm X 250mm for 8mm and 350 mm X 350mm for 24mm]

- - We are ready to design and manufacture various specifications such as label print, press and other machines.

Unit for magnetic cylinder (RDC RB type)

- - It is recommended to use Tsukatani magnetic cylinder to enable the Pinnacle Die to exhibit its superb cutting quality to the maximum.

- - All Tsukatani units are designed to fix corner metals to achieve the stable punching,

- - The anvil roll (reception barrel) is hardened and hard chrome plated to minimize scratches on the surface.

- - Various specifications can be designed and manufactured.

- - 500-kg and 1500-kg digital display load cells are able to be installed.

Load cell (load meter of 500 kg/1500 kg)

- - Converts the amount of force being applied to the sensor into an electrical signal and indicates the amount in digital form.

- - Useful guide for adjusting pressure balance on the operation side and the gear side when setting cutting tools.

- - Two types of load meters (500 kg, 1500 kg) are available.

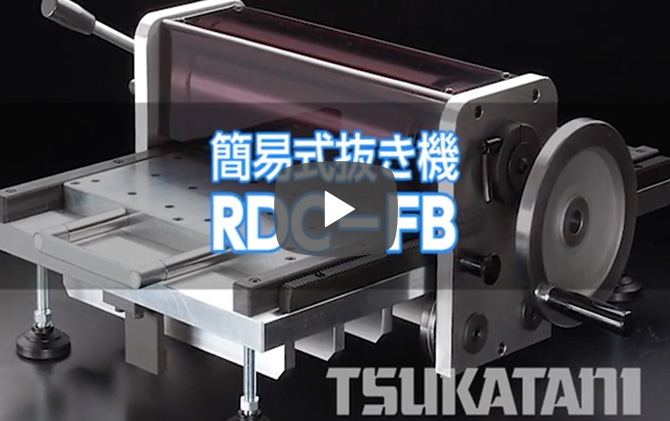

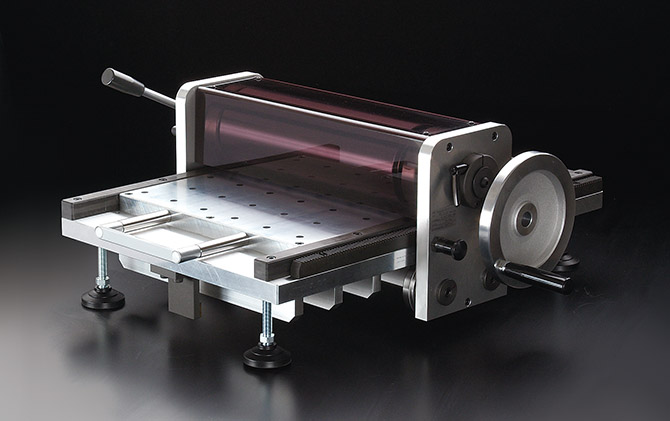

Simple punch unit (RDC-FB type)

- - Test-punching is easily performed on a table.

- - Height is easily adjusted.

- - Both pinnacle die and conventional cutting die can be used.

- - Effective range to punch paper (machine proper size: mm)

A3 type (710 X 726 X 252 72kgs)

A4 type (467 X 418 X 195.5 35kgs)

A5 type (380 X 356 X 190.5 25kgs)

A6 type (318 X 313 X 185.5 14kgs)

Combination of Pinnacle Die

Base through-hole and positioning pin or spring pin

Use base through-holes and positioning pins to set a Pinnacle Die and a plate in parallel, and use the base through-holes and spring pins to keep accurate position during the secondary press.

Wire processing Pinnacle Die and metallic mold

Unite a wire-processed Pinnacle Die with a metallic mold. Half-cut by Pinnacle Die and full-cut by male/female metallic mold solve cutting scrap problem.

Specifications may be changed without prior notice.

Download brochure

- Flexible Pinnacle Die brochure

- PDF : 67.3MB

- Flexible Pinnacle Die order sheet

- PDF : 197KB